The service brake is your car’s main stopping system, using hydraulic pressure to create friction at the wheels so you can slow down and stop safely.

This guide explains how the system works step by step, what each key part does (pads, discs/rotors, calipers, master cylinder, brake fluid, and lines), and the most common warning signs before performance drops.

You’ll also get quick owner checks, how to judge when a symptom is urgent, what typically drives brake repair costs in the UK, and when it’s safest to stop driving and book a trusted local brake inspection.

What Is The Service Brake And How Does It Work?

The service brake is the car’s active braking system that uses hydraulic pressure to create friction at the wheels and reduce speed. In simple terms, you press the brake pedal, the master cylinder converts that push into hydraulic pressure, brake fluid carries the pressure through the lines, and the calipers push the pads onto the rotors to generate friction.

Breaking the system into steps makes it easier to spot faults and understand why routine maintenance matters. Below is a short sequence showing the operational flow and the common failure points linked to each step.

- Press the pedal: the driver starts the braking action by pressing the pedal.

- Master cylinder builds pressure: that mechanical input is converted into hydraulic pressure in the system.

- Brake fluid carries pressure to the calipers: the fluid moves the hydraulic force through the lines to each wheel.

- Calipers press pads onto rotors: friction between pads and rotors slows the car and creates heat that needs to be managed.

This numbered sequence highlights where air leaks or worn parts can interrupt braking performance and sets up a component-by-component view.

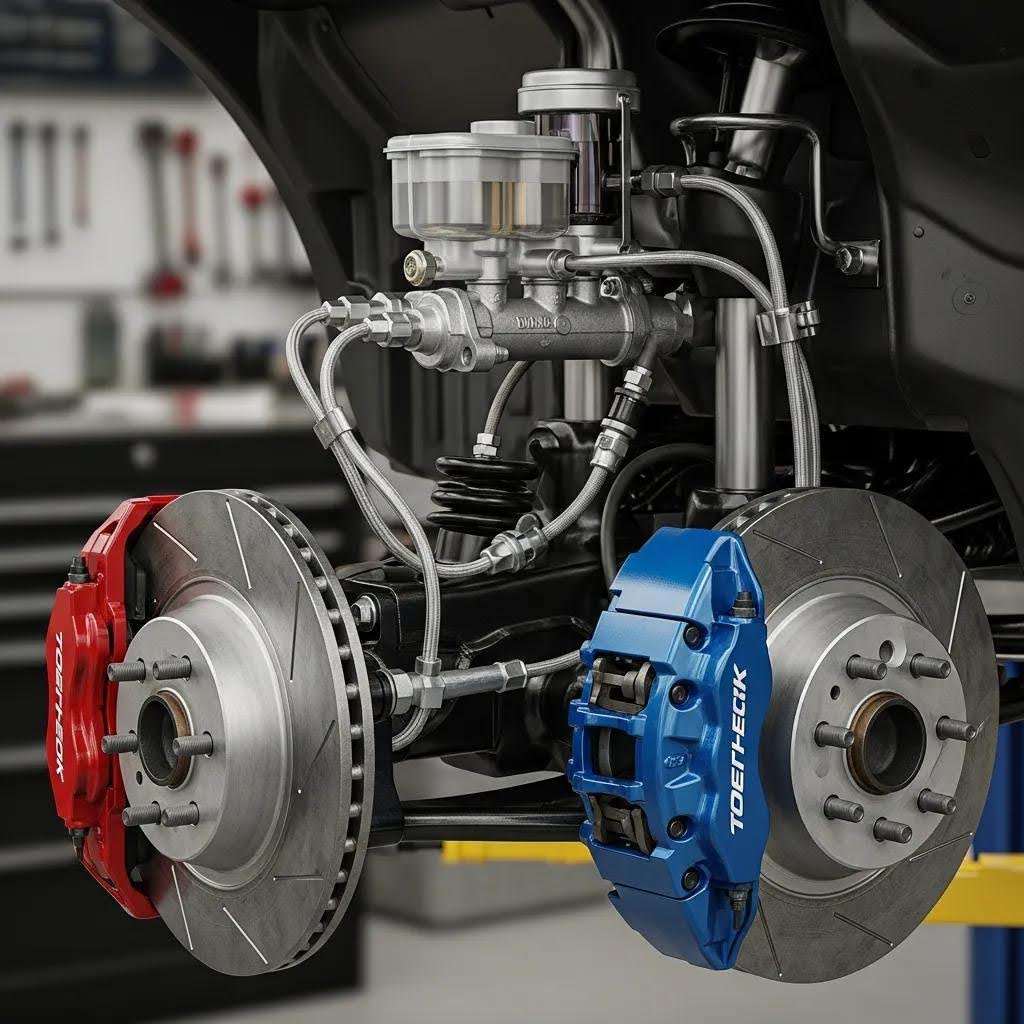

Service Brake System Components

The service brake system consists of several interdependent parts, their condition directly affects stopping performance and safety. Brake pads give the friction surface and wear down with use; rotors (discs) are the mating surface and can warp or score under heat.

Calipers hold pistons that convert hydraulic pressure into mechanical clamping force; the master cylinder is the hydraulic source that creates pressure. Brake fluid transmits that pressure and must be clean; brake lines and rubber hoses carry fluid and can perish or leak.

Knowing each part helps pinpoint likely causes when symptoms appear and guides sensible maintenance choices.

| Component | Primary Function | Typical Wear or Fault Signs |

|---|---|---|

| Brake pads | Provide the friction surface to slow the wheels | Thin lining, persistent squeal, or reduced initial bite |

| Rotors/discs | Provide a contact surface for pads and disperse heat | Scoring, visible grooves, warping, or vibration under braking |

| Calipers | Push the pads onto the rotors via piston action | Seized pistons, uneven pad wear, or leaking seals |

This table helps you spot likely problem areas and focus inspections when diagnosing braking issues.

Hydraulic Service Brake Operation Step by Step

Seeing the system step by step shows how pedal force becomes braking torque and where failures commonly occur. When you press the pedal, force transfers to the master cylinder, which pressurizes brake fluid.

That fluid flows through the lines to the wheel calipers; the pistons in the calipers push the pads against the rotors, and friction slows the vehicle.

If air gets into the circuit, it reduces pressure transfer and gives a spongy pedal; leaks reduce system pressure and lower braking effectiveness. Regular inspection and bleeding restore hydraulic function and reduce the risk of sudden failure.

Common troubleshooting notes:

- Spongy pedal → most likely air in the lines or low/contaminated fluid.

- Hard pedal or little bite → possible caliper seizure or master cylinder issue.

- Pulling to one side → uneven caliper action or pad wear.

These practical checks point owners toward the right diagnostic steps and prepare them to recognise key service-brake symptoms.

Research into hydraulic brake systems highlights how vibration patterns can help diagnose specific faults.

What Are The Common Signs Of Service Brake Failure?

Service brake problems usually show up as sound, feel, or visible clues that need prompt attention. The main warning signs are unusual noises when you brake, a soft or spongy pedal, the car pulling to one side, warning lights on the dashboard, and visible fluid leaks.

Each symptom maps to likely causes, worn pads or discs, air or contamination in the fluid, seized calipers or damaged lines, and recognising how urgent each sign is helps you decide whether to stop driving or book an inspection. The list below summarises common signs with brief likely causes for quick reference.

- Squealing or grinding noises when braking, usually worn pads or metal-on-metal contact.

- Spongy or soft brake pedal, often air in the hydraulic system or low/contaminated fluid.

- Pulling to one side or vibration under braking, typically uneven pad wear or warped rotors.

These symptom notes make it easier to prioritise immediate actions and introduce safe visual checks you can do before visiting a garage.

Warning Symptoms That Need Brake Attention

Classify some symptoms as urgent and others as needing prompt service. Loud grinding, a sudden loss of braking feel, or major pedal travel are urgent, stop as soon as it’s safe to do so and get roadside help if needed, because metal contact or rapid fluid loss can cause a sudden failure.

Persistent squealing, a hot smell from the brakes, or reduced initial bite indicate wear and should be inspected within a few days. Vibration or pulling usually points to uneven wear and will worsen if left; book a brake check to prevent more expensive damage.

If you spot any urgent signs, stop driving and arrange an inspection straight away; less severe signs still need early attention to avoid higher costs later. The next section covers simple visual checks for leaks and fluid conditions.

Brake Fluid and Mechanical Issue Checks

Simple visual and tactile checks often catch fluid or mechanical issues before they escalate and help you decide whether it’s safe to drive. With the bonnet open, check the brake fluid reservoir level; a consistently low level can mean pad wear or a leak. Look for damp or wet areas around the wheels or along underbody lines that suggest a fluid leak.

Dark or amber fluid colour indicates contamination and a reduced boiling point. If you see leaks, feel a pulsing pedal, or notice sudden changes in pedal behaviour, book professional diagnostics without delay.

Doing these checks regularly lowers the chance of unexpected failure and helps you describe the problem clearly to a technician, which speeds up diagnosis. Below is a quick summary of owner checks.

Quick summary of owner checks:

- Check the fluid reservoir level and the fluid colour.

- Look for wetness or drips near each wheel and along brake lines.

- Note any change in pedal feel and watch for dashboard brake warning lights.

If a check confirms a leak or a severe change in pedal feel, arrange an inspection immediately to keep you and others safe.

What Is The Difference Between Service Brakes And Parking Brakes?

Service brakes and parking brakes serve different safety roles: the service brake is the primary, dynamic system used to slow and stop the vehicle while driving, whereas the parking brake is a secondary system intended to hold the vehicle stationary.

Service brakes usually rely on hydraulic components (master cylinder, fluid, calipers, pads, and rotors) and are used every time you stop.

The parking brake is commonly a mechanical cable, an electric actuator, or a small drum inside the rear caliper that locks the wheels when parked. Knowing the difference explains why both systems are checked during an MOT or servicing visit.

This comparison helps you understand why keeping both systems in good order matters, especially on slopes or when towing.

Functional Differences Between Service and Parking Brakes

Service brakes slow and stop a moving vehicle using hydraulic friction at the wheels; parking brakes hold a stationary vehicle using a mechanical or electrical locking mechanism.

Activation is different, too, the service brake is pedal-operated and hydraulic, while the parking brake is engaged by a lever, pedal, or push-button that uses a cable or actuator. Because parking brakes are used less often, they can seize, stretch, or need adjustment, so occasional checks or lubrication are useful.

Keeping both systems maintained ensures your car stops reliably in motion and stays secure when parked; the following safety scenarios underline this point.

Why the Difference Matters for Vehicle Safety

Knowing the two systems helps you avoid relying on the wrong system for the wrong job and makes it easier to spot the correct warning signs. For example, a failed parking brake is dangerous on a slope, while degraded service brakes are hazardous at speed; each presents different symptoms and needs different checks.

Routine inspections should include pad thickness, fluid condition, and the parking mechanism operation, so you cover both dynamic stopping and static security. Regular servicing and MOT checks assess both systems so drivers can maintain safe stopping performance and secure parking.

These safety examples underline why timely inspection matters and introduce a practical look at UK brake repair costs.

How Much Does A Car Service Brake Repair Or Replacement Cost In The UK?

Brake repair costs across the UK depend on the parts needed, labour time, the vehicle make, and diagnostic complexity. Small jobs like pad replacement sit at the lower end of the scale; machining or replacing rotors and calipers and/or master cylinder work push costs higher.

Major cost drivers are parts quality (OE versus aftermarket), the need to replace calipers or the master cylinder, diagnostic time for ABS or electronic parking brakes, and labour rates for particular vehicle types. Understanding these factors helps set realistic expectations before you book an inspection.

Main Factors That Affect Service Brake Repair Costs

Several clear factors affect the final price and explain why quotes differ between garages. Parts quality and whether your car needs specialised components are key drivers.

Labour time rises if parts are seized, electronic parking brakes need calibration, or ABS sensors require fault finding. Additional services, such as a brake fluid flush, rotor resurfacing, or full caliper rebuilds, add parts and labour to the bill.

- Parts choice and vehicle-specific components can significantly affect the total cost.

- Labour time and the complexity of diagnostics also influence the price.

- Extra services like fluid changes, rotor machining, or caliper work add further cost.

This list shows why an upfront inspection is important to produce an accurate quote and highlights the value of local expert help.

Reliable Service Brake Repairs in Ashford, Kent

If you’re in Ashford, Kent, a local Bosch Car Service centre can carry out brake inspections, pad and disc replacement, and full visual and mechanical checks by experienced technicians , Ivydene Garage Ltd offers these services from Unit 99, Ellingham Industrial Estate, Ellingham Way, Ashford, Kent, TN23 6LZ, call 01233 636081 to arrange an inspection.

Their Bosch affiliation and diagnostic equipment help find faults accurately, and the technicians will give clear recommendations and a written quote for any work required.

If you need a brake inspection or a quote, phone the team to book an MOT-style check or diagnostic, acting quickly reduces safety risk and avoids higher repair bills later.

| Service | Cost Drivers | Typical UK Cost Range |

|---|---|---|

| Pad replacement | Pad material, number of axles, and labour | Lower to mid-range, depending on the vehicle |

| Disc/rotor replacement or machining | Rotor size/spec, machining versus replacement | Mid to higher range for replacement work |

| Caliper or master cylinder work | Component cost and labour complexity | Higher range; price varies by parts and labour |

Key takeaways on costs:f

- Ask whether quoted parts are OE or aftermarket and choose accordingly.

- Request a diagnostic inspection before agreeing to major repairs.

- Consider combining a brake fluid change with pad/rotor work for better value.

If you notice any warning signs described earlier in this guide, book a brake inspection promptly to stay safe and meet MOT requirements. For local help in Ashford, call Ivydene Garage Ltd to request an inspection or a quote.

Frequently Asked Questions

What Maintenance Is Required For Service Brakes?

Basic maintenance includes checking brake pad thickness, inspecting rotors for scoring or warping, and monitoring brake fluid level and condition. Clean, dry fluid and adequate pad thickness prevent many common problems.

Have a qualified technician inspect the brakes at least once a year or follow your vehicle manufacturer’s schedule, more often if you drive in heavy traffic or tow regularly.

How Can I Tell If My Brake Pads Need Replacing?

Brake pads usually need replacing when the lining gets thin, around 3mm or less is a common rule of thumb. Other signs are a high-pitched squeal, a grinding sound (which often means metal contact), or reduced braking response. A quick visual check through the wheel spokes can give you a good idea; when in doubt, get a pro to measure the thickness..

What Should I Do If My Brake Warning Light Comes On?

A brake warning light can mean low fluid, worn pads, or a system fault. Safely stop and check the brake fluid level; if it’s low, top it up with the correct fluid and check for obvious leaks. If the light stays on, or you notice strange braking behaviour, call a mechanic for a proper inspection, don’t ignore the warning.

Can I Drive With A Spongy Brake Pedal?

You should avoid driving with a spongy pedal. It often indicates air in the lines or low/contaminated fluid, both of which reduce braking effectiveness. If the pedal feels soft or the travel is longer than usual, stop when it’s safe and arrange an inspection, continuing to drive risks further degradation or failure.